First Aid

It is important for all contractors & workers to understand the company’s first aid procedures and be able to easily access these procedures for reference in the event of an incident involving injury to a worker. It is recommended you save a bookmark to this page on your phone for quick reference.

First Aid Kits

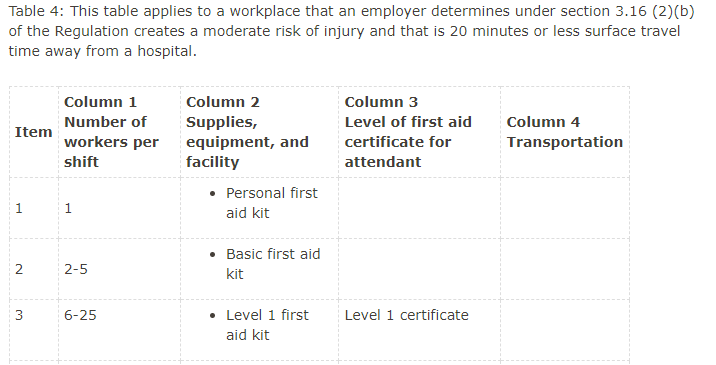

Per the OHS Regulation a First Aid kit is available at each site.

First Aid Kits are located within each company vehicle. Kits are to remain fully stocked - if you use something, or notice something is missing, notify the site supervisor immediately.

Based on an assessment of number of workers, classification of industry, and risk assessment, each vehicle is stocked with a Basic kit (based on CSA Z1220 Type 2: Basic first aid kit — Medium) The classification unit is 721043 and the risk level is Moderate.

First Aid Assessment

General Conditions

There are generally 1-3 workers present on a job site. Worker location varies according to the location of the job. Typically all workers are on the same job site. Jobs can be at residential, new construction, or commercial locations.

Risks & Hazards

Workers at Stillbuilt Solutions, within the HVAC field, face a variety of hazards and risks on job sites, both in residential and commercial settings. These hazards can range from physical and chemical to ergonomic and environmental. Common workplace hazards and risks include:

Physical Hazards

Electrical Hazards

Risk of electric shock or electrocution from working with live wires and electrical components.

Improper grounding and faulty wiring.

Falls and Slips

Working on ladders, scaffolding, or rooftops poses a risk of falling.

Slips and trips due to wet or uneven surfaces.

Confined Spaces

Working in tight spaces such as crawl spaces, attics, and basements can lead to restricted movement and potential for asphyxiation.

Manual Handling

Lifting and carrying heavy equipment can lead to musculoskeletal injuries.

Machinery and Tools

Risks from using power tools and machinery, including cuts, abrasions, and amputations.

Chemical Hazards

Refrigerants

Exposure to refrigerants, which can cause respiratory issues, skin irritation, and frostbite.

Potential for leaks leading to inhalation of toxic gases.

Cleaning Agents and Chemicals

Use of various chemicals for cleaning and maintenance that can be harmful if inhaled or if they come into contact with skin.

Asbestos

Disturbing old insulation materials can release asbestos fibers, leading to respiratory diseases.

Ergonomic Hazards

Repetitive Motions

Tasks involving repetitive motions can lead to repetitive strain injuries.

Awkward Postures

Working in awkward positions, often required in tight spaces, can cause musculoskeletal problems.

Environmental Hazards

Extreme Temperatures

Working in extreme heat or cold, particularly in non-climate-controlled environments.

Poor Ventilation

Risk of working in areas with poor ventilation, leading to respiratory issues.

Biological Hazards

Mold and Fungi

Exposure to mold and fungi, especially in damp or water-damaged areas.

Pests

Encounters with insects, rodents, and other pests that can cause bites or transmit diseases.

Safety Hazards

Noise

Exposure to high levels of noise from machinery and equipment.

Fire and Explosions

Risks from flammable materials and gases.

Psychological Hazards

Stress

High-pressure environments, tight deadlines, and physically demanding work can lead to stress and mental fatigue.

Protective Measures

To mitigate these risks, HVAC workers should:

Use appropriate Personal Protective Equipment (PPE) such as gloves, safety glasses, hard hats, and respiratory protection.

Follow proper procedures for electrical safety and lockout/tagout.

Ensure ladders and scaffolding are stable and used correctly.

Use ergonomic tools and practices to reduce strain.

Receive training on handling chemicals and refrigerants safely.

Ensure good ventilation in work areas.

Follow guidelines for working in confined spaces.

Be aware of their environment and work conditions to anticipate and manage risks effectively.

Injuries

Workers at Stillbuilt Solutions, within the HVAC field, may be exposed to a variety of risks on the job that can lead to different types of injuries. These injuries can result from physical, chemical, ergonomic, and environmental hazards commonly encountered in the HVAC industry. Here are the types of injuries that are likely to occur for an HVAC worker:

Physical Injuries

Electrical Injuries

Electric shock and electrocution from working with live electrical components.

Burns from electrical arcs.

Fall-Related Injuries

Fractures, sprains, and strains from falling off ladders, scaffolding, or rooftops.

Head injuries from falls or falling objects.

Cuts and Lacerations

Injuries from sharp tools, sheet metal edges, and handling HVAC components.

Abrasions from contact with rough surfaces.

Bruises and Contusions

Impact injuries from tools, equipment, or materials.

Crush Injuries

Injuries from heavy equipment or components falling or being dropped.

Compression injuries from working in tight spaces.

Eye Injuries

Particles, dust, or chemical splashes causing eye injuries.

Burns from hot components or refrigerants.

Chemical Injuries

Skin Burns and Irritations

Chemical burns from exposure to refrigerants, cleaning agents, and other chemicals.

Dermatitis from prolonged contact with irritating substances.

Respiratory Injuries

Inhalation of toxic gases from refrigerants or other chemicals.

Respiratory issues from exposure to mold, dust, and fumes.

Musculoskeletal Injuries

Repetitive Strain Injuries (RSIs)

Injuries from repetitive tasks such as installing, servicing, and repairing HVAC systems.

Conditions like carpal tunnel syndrome or tendinitis.

Back and Neck Injuries

Strains and sprains from lifting heavy equipment and working in awkward positions.

Chronic back pain from poor ergonomics.

Environmental Injuries

Heat-Related Injuries

Heat exhaustion and heat stroke from working in hot environments without proper ventilation.

Dehydration and heat cramps.

Cold-Related Injuries

Frostbite and hypothermia from working in extremely cold conditions.

Biological Injuries

Allergic Reactions

Reactions to mold, dust, and other allergens commonly found in HVAC systems.

Bites and Stings

Injuries from insects, rodents, or other pests encountered during inspections or repairs.

Noise-Induced Injuries

Hearing Loss

Long-term exposure to high levels of noise from machinery and equipment can lead to hearing impairment.

Psychological Injuries

Stress and Fatigue

Mental and physical stress from high-pressure environments, tight deadlines, and physically demanding tasks.

Fatigue from long hours and strenuous work conditions.

Preventive Measures

To reduce the risk of these injuries, HVAC workers should:

Use appropriate PPE (Personal Protective Equipment) such as gloves, safety glasses, hearing protection, and respirators.

Follow proper safety protocols for electrical work, including lockout/tagout procedures.

Use correct lifting techniques and ergonomic tools to prevent musculoskeletal injuries.

Ensure proper ventilation and take breaks to avoid heat-related injuries.

Receive training on the safe handling of chemicals and refrigerants.

Be aware of their surroundings and the potential hazards in their work environment.

Barriers

Providing first aid to an injured worker at a residential, commercial, or construction job site can be hindered by various barriers. These barriers can significantly impact the timely and effective delivery of first aid, potentially worsening the injury or condition. Here are some possible barriers:

Physical Barriers

Accessibility Issues

Difficulties in reaching the injured person in confined or elevated spaces, such as attics, basements, or rooftops.

Obstacles like debris, equipment, or structural elements blocking access.

Location of the Site

Remote or isolated job sites far from medical facilities or emergency services.

Poor infrastructure or rugged terrain making it hard for emergency responders to arrive quickly.

Environmental Barriers

Weather Conditions

Extreme weather conditions (heat, cold, rain, snow) complicating rescue efforts and first aid provision.

Visibility issues due to poor lighting, fog, or dust.

Noise Levels

High noise levels from machinery or construction work making it difficult to communicate effectively.

Resource Barriers

Lack of First Aid Supplies

Inadequate or missing first aid kits on site.

Insufficient medical supplies and equipment to handle specific injuries.

Absence of Trained Personnel

Lack of trained first aid responders on site.

Insufficient number of workers with first aid training.

Communication Barriers

Language Barriers

Language differences between the injured worker and the first aid provider.

Difficulty in understanding or conveying the nature and severity of the injury.

Poor Communication Systems

Inadequate communication tools or devices (e.g., radios, phones) to call for help.

Interference with signal or connectivity issues in remote areas.

Psychological Barriers

Panic and Stress

Panic or stress among co-workers affecting their ability to provide effective first aid.

Injured worker’s anxiety or shock hindering cooperation with the first aid provider.

Fear of Liability

Fear of legal repercussions preventing bystanders from offering assistance.

Concerns about causing further injury or not knowing the proper first aid techniques.

Organizational Barriers

Lack of Safety Protocols

Absence of established emergency response plans and procedures.

Poorly implemented or communicated safety policies.

Delayed Response

Slow response from management or emergency services.

Bureaucratic delays in coordinating rescue and medical help.

Cultural and Social Barriers

Cultural Beliefs

Cultural beliefs or practices influencing the willingness to accept or provide first aid.

Gender dynamics where assistance might be delayed due to cultural norms.

Social Stigma

Social stigma associated with certain injuries or conditions, deterring prompt aid.

Training and Knowledge Barriers

Lack of Confidence

Insufficient confidence among workers to perform first aid due to inadequate training.

Fear of making mistakes during first aid procedures.

Knowledge Gaps

Lack of knowledge about the specific first aid requirements for different types of injuries.

Inadequate understanding of the use of first aid equipment.

Preventive Measures

To overcome these barriers, it is crucial to:

Ensure first aid kits and emergency supplies are well-stocked and accessible.

Provide comprehensive first aid training to workers regularly.

Develop and communicate clear emergency response plans and safety protocols.

Facilitate effective communication systems and tools on-site.

Foster a safety culture that encourages prompt and proper first aid response.

Transportation

Most job sites being within 20 minutes of a hospital facilitates relatively prompt medical response and transportation for injured workers. However, the exact time required can vary depending on several factors such as location, traffic conditions, and the severity of the injury. Here are the potential times and methods of transportation available for transporting an injured worker to medical treatment:

Estimated Time for Transportation

Response Time for Emergency Services

Ambulance Arrival Time: Typically, 5-15 minutes in urban areas. Response time can be longer in remote or heavily congested areas.

Preparation and Loading Time: 5-10 minutes for paramedics to stabilize and prepare the injured worker for transport.

Transportation Time to Hospital

Urban Areas: 10-20 minutes depending on traffic and distance to the nearest hospital.

Remote or Congested Areas: Up to 30 minutes or slightly more during peak traffic hours or from more remote job sites.

Methods of Transportation Available

Emergency Medical Services (EMS) / Ambulance

Use Case: For serious injuries or conditions requiring immediate medical attention.

Advantages: Equipped with medical equipment and trained paramedics, providing immediate care en route to the hospital.

Company or Personal Vehicle

Use Case: For less severe injuries where the worker can be safely transported without the need for medical intervention en route.

Advantages: Often faster to arrange, especially for minor injuries. Suitable for transporting to nearby clinics or hospitals.

Taxi or Rideshare Services

Use Case: When an ambulance is not necessary, and company/personal vehicles are unavailable.

Advantages: Readily available in urban areas, providing a quick transport option.

On-Site Medical Response Team (if available)

Use Case: On larger commercial or construction sites where an on-site medical team is present.

Advantages: Immediate first aid and stabilization, potentially faster than waiting for an external ambulance.

Local Hospitals

Royal Jubilee Hospital: Located in Victoria, provides a range of emergency and specialist medical services.

Victoria General Hospital: Another major hospital in the area, offering comprehensive emergency care.

Saanich Peninsula Hospital: Located in nearby Saanichton, providing emergency services.

Considerations for Timely Transportation

Traffic Conditions: Peak hours, construction zones, and road closures can significantly affect travel time.

Accessibility of Job Site: Easy access to major roads and highways can expedite transportation.

Preparedness: Having a well-established emergency response plan, including clear directions and contacts for the nearest hospitals and EMS, can save crucial time.

Communication Systems: Efficient communication tools to quickly summon emergency services or arrange alternative transportation. All workers must have a charged, functioning cell phone with them on site at all times.

Stillbuilt Solutions will review and update this assessment:

(a) within 12 months after the previous assessment or review, and

(b) whenever a significant change affecting the assessment occurs in the employer’s operations.

First Aid Procedures

Stillbuilt Solutions, based in Saanichton BC, is committed to providing a safe working environment for all employees, especially those working on residential, commercial, or new construction job sites. This first aid plan outlines the procedures and responsibilities to ensure timely and effective first aid response in the event of an injury.

Worker Input and Regular Meetings

Worker input on first aid procedures is encouraged and will be obtained during:

Regular monthly meetings (as required by Section 3.2 of the Regulation)

Job safety analysis sessions

Tailgate meetings

Toolbox talks

Pre-job safety meetings

Annual First Aid Re-assessment

Following Drills, Incident Investigations, or whenever changes to the work requires it

First Aid Kits

First aid kits are located in each company vehicle.

Kits are regularly inspected and replenished as needed.

First aid kits include supplies suitable for a variety of injuries (e.g., bandages, antiseptics, burn dressings, etc.).

Worker Training

All workers must demonstrate a basic understanding of first aid skills prior to commencing work.

Training includes CPR, wound treatment, and the use of first aid equipment.

Workers are trained on the first aid procedures and the use of emergency communication tools.

Calling for First Aid

Emergency Number: Call 911 for emergencies.

On-Site Communication: Use a cell phone or talk to another person on-site who can coordinate the response.

First Aid Attendant Authority: The first aid attendant has authority over the treatment of injured workers until responsibility is handed over to emergency medical personnel or a person with higher or equivalent first aid certification.

Barriers to First Aid

If there are any barriers to providing first aid (e.g., physical obstacles, remote locations), discuss how injured workers will be accessed and moved.

Plan for potential barriers during safety meetings and develop strategies to mitigate these barriers. Barriers should be noted in daily site inspection reports.

Transportation for Injured Workers

Call for Transportation: The first aid attendant or a designated person is responsible for arranging transportation.

Methods of Transportation:

Ambulance: For severe injuries or conditions requiring immediate medical attention.

Company or Personal Vehicle: For less severe injuries.

Taxi or Rideshare: If company vehicles are not available.

Emergency Transportation: If required by Section 3 of Schedule 3-A, the location and method of emergency transportation must be specified and accessible.

Prearranged Routes: Prearranged routes to the nearest medical facilities are identified and communicated to all workers.

Equipment, Supplies, Facilities, and Services Available

First Aid Attendants: Trained and certified first aid attendants are not always available on-site. Their names and certification levels are documented where workers with OFA certification are employed.

First Aid Equipment: Located in company vehicles, including bandages, antiseptics, CPR masks, gloves, and other necessary supplies.

Facilities: Nearest hospitals and clinics are Royal Jubilee Hospital, Victoria General Hospital, and Saanich Peninsula Hospital. Urgent Care clinics are also available throughout the region.

Procedures for Obtaining First Aid

Minor Injuries: Workers should report minor injuries to the first aid attendant or fellow worker, who will assess and provide necessary treatment.

Serious Injuries: In case of serious injuries, the first aid attendant will stabilize the injured worker and arrange for emergency transportation.

First Aid Record: A first aid record must be created for all injuries, illnesses, and exposures reported or treated.

Whenever a first aid kit is used, an incident report must be filed.

First Aid Attendant Responsibilities

Response to Calls: Immediately respond to calls for first aid and provide necessary treatment.

Treatment Authority: The first aid attendant is in charge of managing the injured worker until emergency medical personnel arrive or the worker is safely transported to medical facilities.

Reporting Injuries: The employer must report injuries to WorkSafeBC. Workers must report all injuries to their supervisor and the first aid attendant.

Access and Movement of Injured Workers

Accessibility: Ensure that all areas of the workplace are accessible to emergency services. If any area is not accessible, plan and communicate how injured workers will be moved to an accessible location.

Equipment for Movement: Use stretchers, wheelchairs, or other equipment as needed to move injured workers.

Maintaining the System

First Aid Coverage: Schedule and assign first aid attendants to ensure adequate coverage for each shift.

Training and Certification: Track and schedule recertification of first aid attendants.

Inspection and Maintenance: Regularly inspect and replenish first aid supplies and equipment. Maintain emergency transportation vehicles.

Equity, Diversity, and Inclusion (EDI)

Inclusive Equipment: Ensure first aid equipment, especially PPE, is suitable for all workers.

Accessibility: Provide signage and written procedures in accessible languages.

Worker Engagement: Routinely gather feedback and make enhancements to the first aid program accordingly.

Training on First Aid Procedures

New Worker Orientation: Include first aid procedures as part of new worker orientation.

Regular Reviews: Regularly review procedures with workers to ensure understanding.

Stillbuilt Solutions is dedicated to ensuring the health and safety of its workers by maintaining a comprehensive first aid plan. Regular training, accessible first aid kits, and clear procedures ensure that all workers are prepared to handle emergencies effectively.

Drills

At least once per year, and whenever the procedures change, first aid drills are conducted to ensure that:

(a) the procedures are effective, and

(b) workers, first aid attendants and other persons referred to in the first aid plan are capable of fulfilling their roles and responsibilities

Drill records are maintained to establish compliance with the requirements of section 3.17(4).

Drill records should contain the following information:

• Date and time of drill

• Names and rolls of participants

• Brief summary of scenario tested

• Summary of observations and outcomes, including any deficiencies identified

• Any corrective actions taken